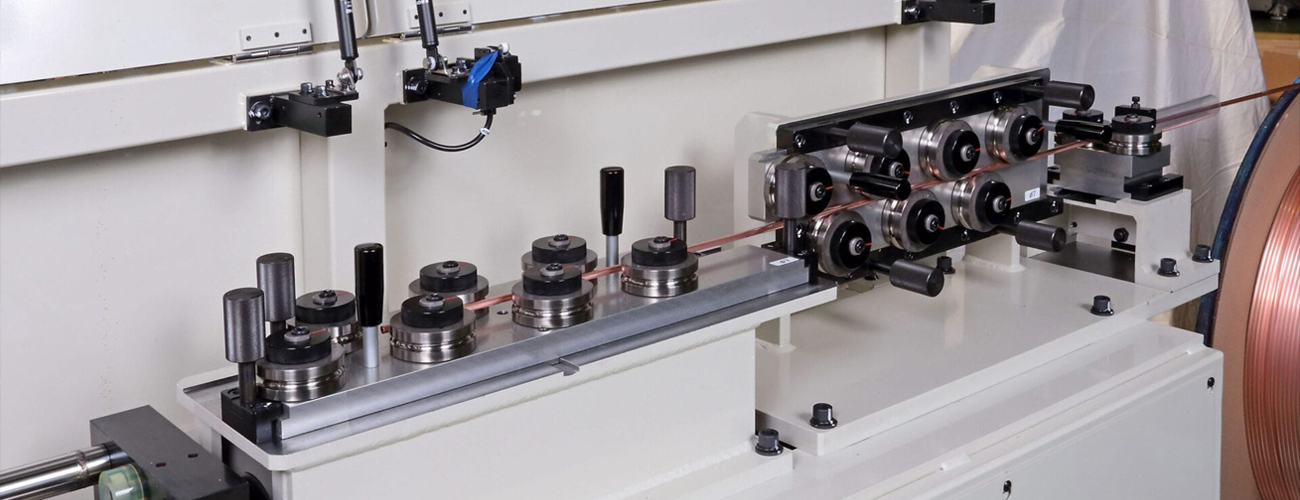

Pull-Apart Tube Cutting – Rotary Cutting

Advantages

The Pull-Apart Tube Cutting method brings many advantages. Since the blades need to cut only up to the tube’s thickness, precise cuts are made much faster than if one were to use a traditional band saw or cold saw. The second advantage of Pull-Apart Tube Cutting is that the blades cutting the tube do not have any teeth, and do not produce metal chips as a result. With no metal chips cluttering the work area and getting onto the tube, very little cleanup is needed once the process is finished.

Another significant advantage of Pull-Apart Tube Cutting is the smooth, clean cut. While Greaney offers extensive tube deburring and finishing services, they may not need to be utilized since this tube-cutting method is so clean. This method is suitable for cutting straight sections of 20-ft to 25-ft metal tubing, or for cutting a coil of tubing, which can be uncoiled and straightened during the cutting process.

Other Advantages of Pull-Apart Tube Cutting Include:

-

No material loss between cuts

-

Can be used on various types of metals including Steel, Stainless Steel, Aluminum, Copper, and Brass.

-

No significant burr

-

Cuts soft materials such as Aluminum and Copper

-

Cuts coiled material or straight lengths

-

Can be integrated with secondary operations such as grooving and chamfering

-

Great for high volume production

Greaney Enterprises can handle small or large projects. Our facility is equipped to handle any size metal cutting volume. Call Greaney Enterprises today for your tube cutting project!